Each stage of the Plastomer manufacturing process is strategically linked and positioned to conform to the goals of Lean Manufacturing, thereby limiting waste in materials and manpower. To see our processes in action, please click the “Watch Video” links below or visit our YouTube channel. All videos are provided by YouTube and may expose you to advertisements unrelated to our business.

Manufacturing

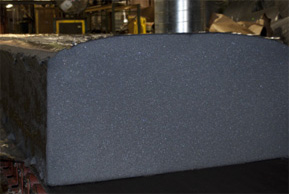

The liquid formulation transforms into large foam buns under sophisticated process monitoring that assures achievement of the required properties.

When Urethane Foams are not the material of choice, Plastomer obtains the desired material from any of a number of partners selected for quality, cost, availability, and delivery.

Laminating

To add the pressure sensitive adhesive (PSA) package to the material, Plastomer maintains its own wet lamination processes in-house, thereby assuring the quality of the final product.

In cases where it is advisable, we will purchase and use dry high performance adhesive systems that likewise achieve desirable customer bonding capabilities.

Quick Response Activities

Plastomer has a long-standing reputation for fast, cooperative solutions. Our 60 years of experience with successful customer relationships, numerous awards, and countless testimonials demonstrate our continued commitment to our customers and products.

TESTIMONIALS – WHAT YOU SAY ABOUT US

“Your support allowed us to rapidly respond to a major customer issue, discovered very close to the start of vehicle production. It’s nice to work with a team that can pull out all the stops and get things done when needed.” – Dave

“I have to thank you so much for your help and your quick response to getting us more topper pads, since our hi-lo driver misplaced the original ones. I haven’t had any supplier react as promptly and with such great customer service as you have for as far back as I can remember.” – Melissa

“We have been receiving nothing but positive answers about how to make things happen; we never received a no as an answer.”

– Chaim

“Please send us the assembly fixture and video you made for us. I am so excited for our operators and cannot wait to introduce them to this new process. You guys are great!” – Nancy

“Your very quick response and customer focus are greatly appreciated.” – Erick

“Just wanted to say ‘Thank You’ to you and your team for pulling off the nearly impossible and getting the parts done so quickly with little notice. In this industry many things seem to go unappreciated, but I sincerely appreciate you helping me out like you did.” – Glen